The keysheet metal any from the top and known materials within the engineering world, simply because they serve a great deal from purpose within our lifestyle. Bed sheet metals are really common when it is00 seen about cars, machinery, house facades, furnishings . It's mainly seen about parts serving as housing.

Mattresssheet metal

In this essay , we all are searching deep into bed sheet metals materials, types, sizes and thickness applications, hot- thrown and cold- rolled bed sheet metals, last but not least forming way of sheet metals.

An manufacture is anticipated to understand the dimensions of the normal measurements, materials, difference which makes, properties and forming method right before considering applying into almost any projects.

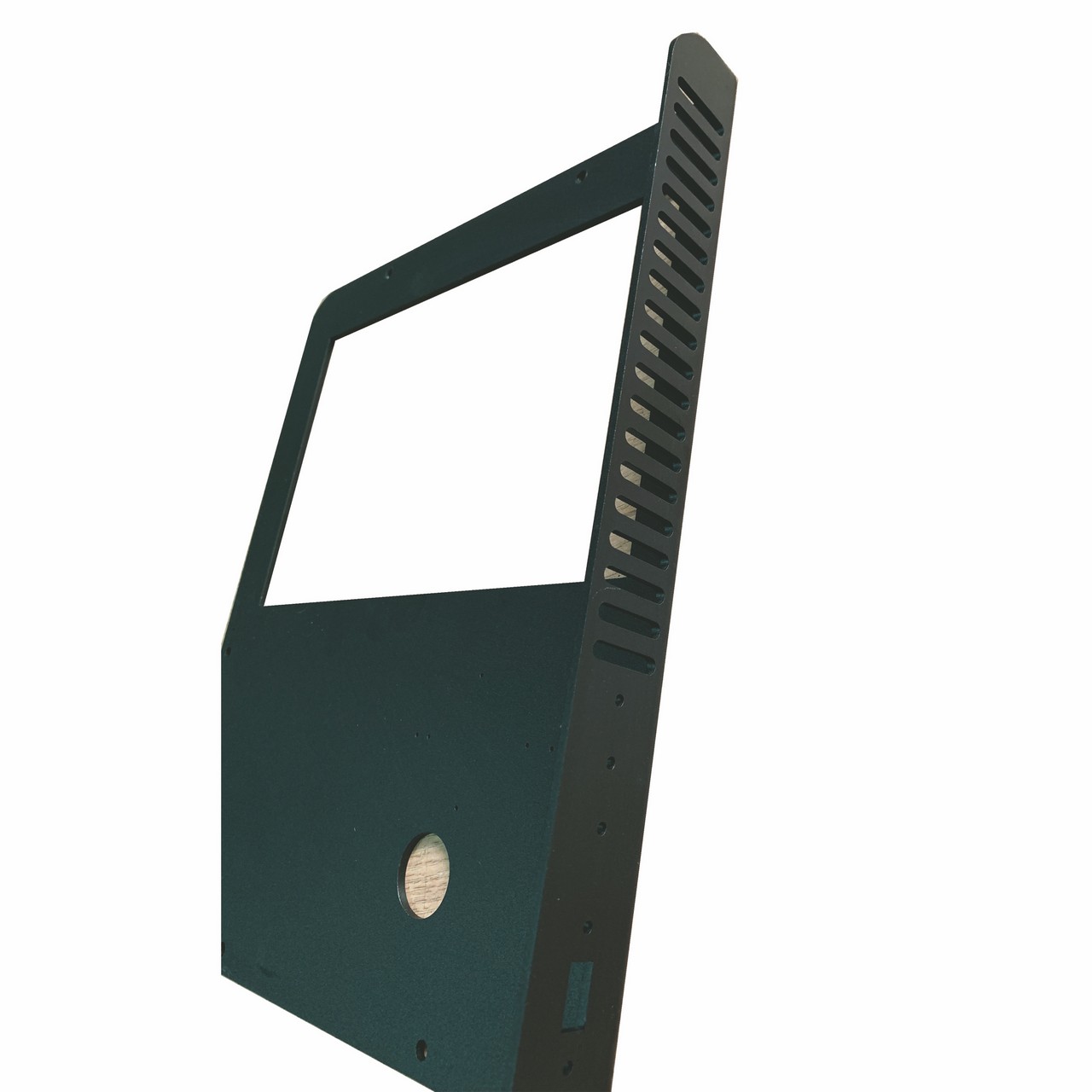

Sheets metals are shaped by an process into skinny, flat pieces, mostly used by simply metalworkers. It may be cut and twisted into lengths and shapes, object making it applicable in order to fabrication jobs.

Contents]hide]

oneApplications

a few Metal Foil, Sheet and Platter

a fewForms of sheet materials

someMaterials

4. 1 Metal steel

4. 2 Aluminium

several Join our Newsletter

5. a particular Brass

6thThickness of your bed sheet metals

sevenHot- thrown and cold- rolled bed sheet metal

Apps

Sheet metals used historically for plate armour donned by cavalry and widely requested decorative purposes.

The applying sheet metals include vehicle and truck( lorry) bodies, therapeutic tables, aeroplane fuselages and wings, roofs for buildings( architecture), and others applications.

Sheet steel manufactured from iron and various many other materials with good magnetic permeability has good applications on electric machines and transformers.

Metal Foil, Sheet and Plate

These materials are available in several thicknesses, ideal thin sheets are believed foil or leaf. Sheet metals fuller than 6 mm( 0. 25 in) are believed plate or strength steel. They are offered during flat pieces or coiled pieces. The coils are formed by running a frequent sheet from metal by way of a roll slitter. Metal foils in many cases are developed with aluminium, the thickness is usually as much as 0. 2 mm

Types of sheet metals

your bedobeying describe here are your bed sheet metal types plus the supplies they are constructed with ,

Products

Different sheet metal materials may be easily changed to sheet steel, metals like aluminium, copper, instruments, tin, nickel, and titanium. Several expensive metals are accustomed to create sheets for decorative functions, the same as silver, gold, and american platinum eagle. Selecting the best sheet metal for your specific project is placed this program and element the item.

Some materials hold the equal mechanical properties as other steel materials inside the project. Merely as steel sheet having substantial tensile durability and strength , object making it suitable for machinery and construction work.

Stainless

the stainless features three levels, grade 304 is the almost all common. It provides good decay resistance because it maintains formability and weldability.# 2B,# 3, and# 4 are its available surface finishes.

The 316 grade possesses additional corrosion resistance and strength for a greater temperature in comparison to 304. You should use that for chemical equipment, marine applications and common on parts the same as pumps, valves etc.

The laststainless of grade 410 is the heat treatable one, but which has a lower corrosion quantity of resistance than the last listed one 's. it really is widely was used to getting creating cutlery.

Well-liked by most, grade 430 has a low supports cost alternative when compared with 300 's grades. It is recognized as at any time high corrosion resistance is definitely not an issue. It may end up becoming utilized for appliance products.

Lightalloy

Aluminium is an additional well- liked metal used to make bed sheet metals because of its freedom, cost- effectiveness, wide range options along with other properties. That's pronounced as aluminium during British English features several grades including,

1100 supports H14, 3003- H14, 5052- H32, and 6061 supports T6

The grade 1100 supports H14 is pure aluminium, very chemical and weather-proof. Which is weldable and ductile plenty of for deep drawing but provides low strength. Its applications are actually mostly on chemical processing products, jewellery, and lightweight reflectors.

If ever affordable and formability is to be looked at, grade 3003 supports H14 must are located in place. That is preferable to the 1100 version, corrosion- resistant as well as weldable. It is normally found in mailboxes, content spun and drawn parts, cabinets, enthusiast blades, stamping etc.

This level 5052- H32 is substantially a lot better than the 3003 for the reason that it still maintaining good formability. The weldability and high corrosion level of resistance can also be in good circumstance through this version. Its applications are already found in electronic chassis, tension vessels and tanks.

The particular level 6061- T6 may be the superior of the grades, as it 's a typical heat supports treated structural aluminum alloy. It is actually weldable, corrosion proof and more than the 5052 version. However , some strength will soon be misplaced when welded also it 's definitely not formable. This aluminum grade is certainly mainly used in modern airplane structures.

Metal

Brass happens to be a copper alloy, which happens to be a also used being a bed sheet metal. It even offers great properties such as for example conductivity, formability, corrosion resistance and possess additional strength.

The problem with bed sheet metals manufactured from brass is the variation in incoming sheet coils properties. The fabric has qualified high rejection rate as a result of observed inconsistent behavior during production. Though you will find discriminating approach for testing incoming sheet information formability.

Widthof sheet materials

Thickness of sheet metals are already specified in millimeters all above the entire world. In USA it is usually specified simply by a conventional, non- thready measure called gauge, the bigger the gauge number the thinner the metal.

The most common used steel sheet steel ranges from 30 to regarding 7 gauges. The gauge is significantly diffent between ferrous and non supports ferrous metals. Non- metallic material such as for instance copper, the thickness is measured in oz, representing the load of water piping. Bits of sheet metals are actually anticipated to keep up uniform thickness to have ideal result when put to operate.

Warm- rolled and cold- rolled sheet steel

The 2 different ways of constructing sheet metals includes hot and cold rolling. Studies have verified that sheets and plates are already hot rolled for cost supports efficiency purposes. the method from construction steels, the cold running process only increases to three mm. for stainless, the going process starts from 3 mm and covers the sheet with cool rolling, in example, about 6 mm.

Engineers will be able to differentiate those two processes for accurate purposes. The very lastcold rolled terme conseillé are desired as the very last dimension could be controlled. However , in hot rolled steels, the scale and condition might alter after cooling, ultimately causing a little shrinks.

Visit my recommendation

I seriously hope you found this placed interesting in addition to attained expertise. In that case, it is possible to widely offer you a justification in our brief review section and please share along with other students. Thanks!

Also verify:

Knowingelectric arc welding

Almost all you need to know regarding rolling process

Knowingscrew and bolt

Several types of bed sheet metals work equipment

Diversevarieties of Casting tools and products

ComprehendingFiling tools

ComprehendingSoldering process