1 ) Overview and Qualities

Injection molding can be a forming process applying molds. Materials for instance synthetic resins (plastics) are heated and even melted, and next provided for the mould where they will be cooled to make the designed condition. Due to typically the resemblance for the method of injecting essential fluids by using a new syringe, this procedure is definitely called injection creating. The flow with the process is while follows: Materials will be melted and added to the mold, in which they harden, and even then these products will be taken out and even finished.

With injections molding, diversely designed parts, including people that have complex shapes, may be consistently and swiftly created in huge volumes. Therefore, injections molding is employed to be able to manufacture commodities and even products in a new variety of companies.

2. Injection Creating Machines

Injection creating machines come inside several types, these kinds of as motorized equipment driven by domestico motors, hydraulic equipment driven by hydraulic motors, and cross types machines driven by simply a combo of your servo motor plus a hydraulic motor. Typically the structure of the injection molding equipment may be briefly described as consisting regarding an injection product that sends typically the melted materials to the mold, and a new clamping unit of which operates the mould.

In recent times, using COMPUTER NUMERICAL CONTROL has become increasingly followed in injection creating machines, giving climb for the popularity regarding models that grant high-speed injection underneath programmed control. About the other palm, a number regarding specialized machines, these kinds of as models of which form the mild guide plates intended for LCD monitors, twice.

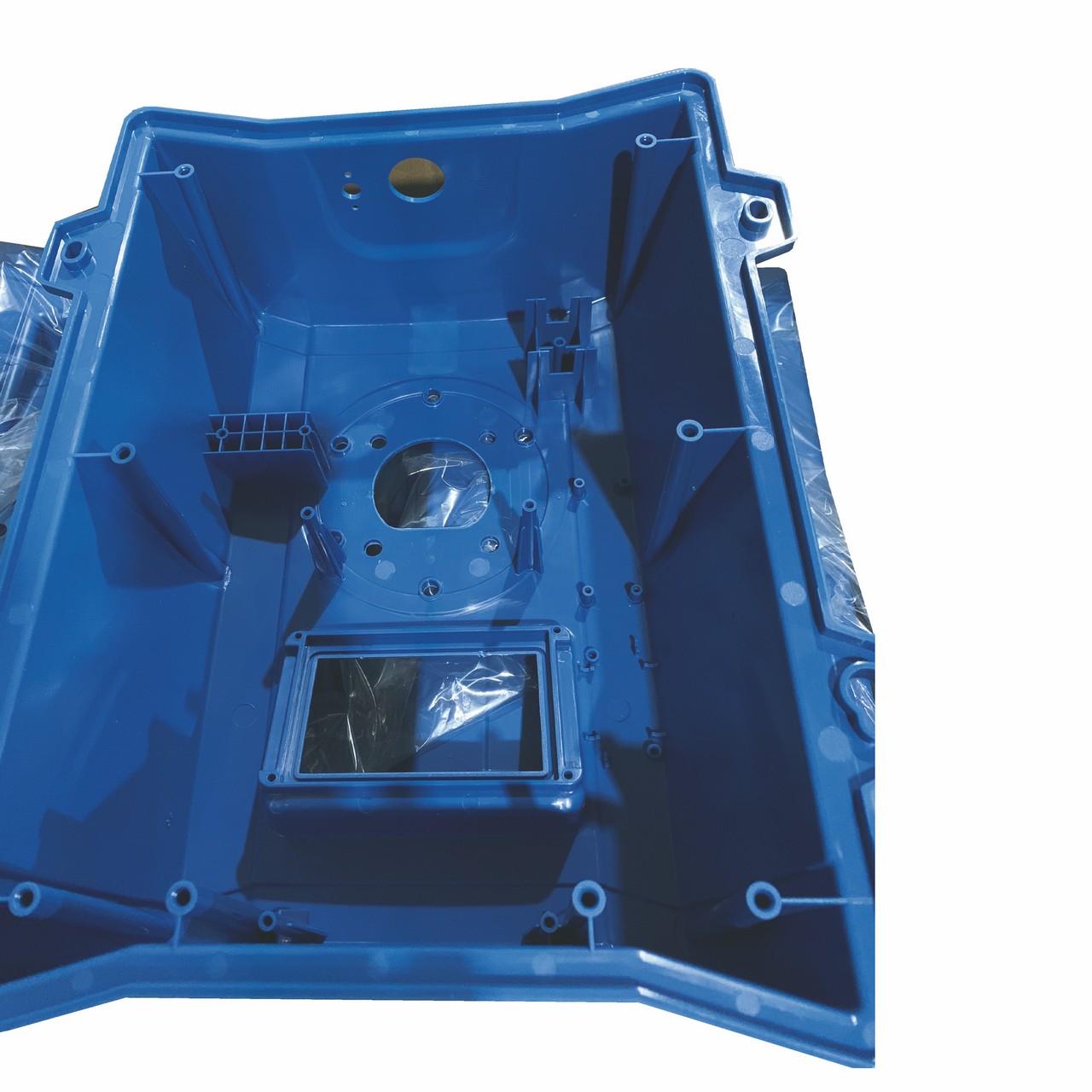

Basic Structure regarding Injection Molding Equipment

Basic Structure regarding Injection Molding Equipment

A Cylinder (heats the material)

N Nozzle (injects typically the melted material)

G Hopper (material feeder)

D Mold (material is poured to the mold cavity in between two plates)

several. Injection Molding Method

Injection molding begins with resin pellets (granules) being added into the hopper, the entry level for the stuff. The pellets will be then heated and even melted inside tube in preparation intended for injection. The stuff can then be forced by way of the nozzle regarding the injection product before being sent through a funnel inside the mold referred to as a sprue and even then through branched runners into typically the mold cavity. Following the material lowers and hardens, typically the mold opens, and even the molded element is ejected in the mold. To surface finish the molded element, the sprue and even runner are cut in the part.

That is important of which the melted stuff is evenly sent through the entire mold while often times generally there is more as compared to one cavity in the mold enabling the production regarding more than one particular part at a new time. Therefore, typically the mold condition needs to be designed in a new way that assures this, for instance by simply having runners regarding the identical proportions.

While injection creating is well suited for size production, you have to include a good comprehension of the various situations instructed to produce high-precision products, which incorporate the selection regarding resin material, typically the processing precision regarding the mold, and even the temperature and even speed of typically the melt injection.