Expense casting any option intended for producing intricate parts and parts. There are several specific actions in process to design and create the desired workpieces. This is known as such workpieces will undoubtedly be created in regards to shelled spreading, that is later removed if the workpieces have now been put to the mold plus they are arranged.

Steps 1: Causing the Die/ Pattern

The critical first step to the process is to generate the die or pattern of the required workpiece. The pattern is generally made from wax. It could be poured right into a expire using injection molding, carved by just hand from the block in wax, or printed 3D inkjet printer and the right wax materials.

step two: Mounting the Polish Patterns

Investment casting tooling entails creating multiple wax patterns and attaching these onto a "gate" device. This product is wherever metal or many other materials will definitely be poured to eventually produce the required workpieces.

Step a couple of: Tree Assembly

The tree setup finishes the mounting from your polish patterns within the "gate" gadget. It is named a woods at this because every person wax pattern is actually a "branch" and will end up one finished workpiece once the procedure is finalized. You may have seen tree assemblies on new games that are looking to have pieces detached before utilize .

Next step: Shell Molding

If the tree is assembled, the next thing is to place the shelled casting surrounding this. First, the tree is dropped right into a ceramic slurry. Then it is dipped in to a stucco of mud. The molding must fully dry before you use it. Both of these processes could be completed too often times before mold is solid enough to take care of casting tensions.

Step five: Wax Removal

Ahead of the desired material could possibly be put to the newly shelled mildew, the wax patterns must be removed first. Normally, this is often created by heating the wax in a oven. Vapor employed to heat the wax. The mold is inverted the liquid wax can flow away from it and be utilized again to produce new wax habits.

Another solution procedure for wax removing is always to heat the polish it "burns" off and is normally fully taken off the shelled casting.

Step six: Mold Spreading

Following wax continues to be eliminated, you will see open areas shelled casting within the from your formal wax patterns. Molten metallic yet another liquid material is normally poured in to the casting. The fabric remains in the casting till they have fully cooled and solidified.

Step seven: Removing the Shelled Casting

Everything thathammer another tool to take away the shelled casting until everything is normally left is the first woods. Instead of the polish patterns, people now function as finished workpieces attached with in a bad neighborhood. Following your casting remains eliminated, the workpieces are carefully slice from the tree.

Step eight: Finishing Operations

Each workpiece is normally inspected for imperfections. If almost any are located, they're discarded, and the items is reused. The final step up the investment casting process is to utilize different finishing methods upon the workpieces. They could be sanded, covered, smoothed, machined, etc. to complete the required results.

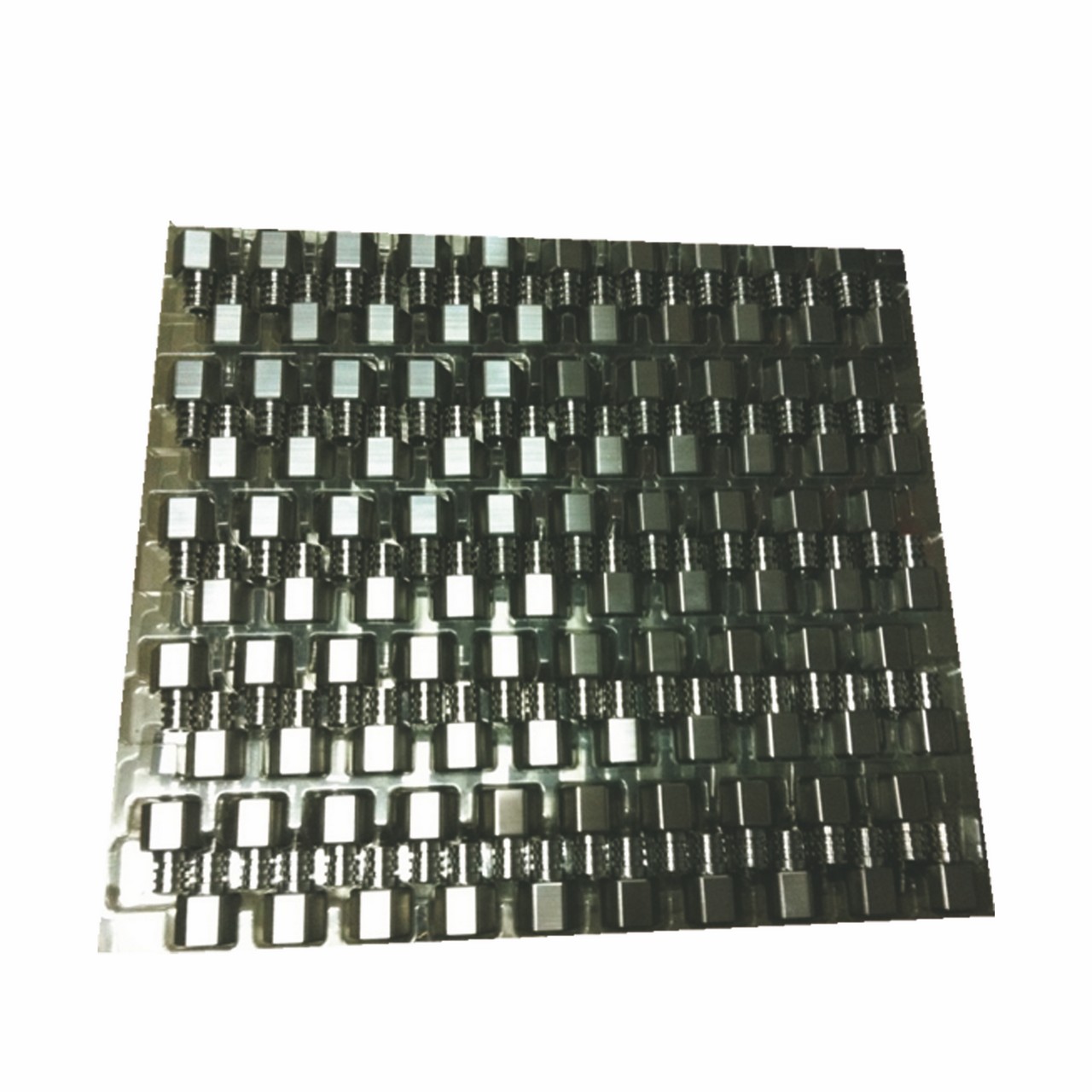

metalliccomponent created by lost wax procedure

Investment cast tooling is perfectly- suitable for vast amounts or simply intricate workpieces that require precision information. Steps in the task can and perform vary dedicated to the complexity from the workpieces being created.

We provide services, including product design, rapid prototyping, shot molding, investment casting, CNC engineering, secondary and finishing operations, plus more!