Fine, CNC Operator, Start off Your Day!

Following punching in and using safety items, you report to your assigned work center. A 12-15 minutes is getting the supplies you may need for the day and talking with the previous transfer operator who stocks and shares any machine or part quality issues you need to know.

This team-work allows a COMPUTER NUMERICAL CONTROL operator to plan tool changes and audits for maximum efficiency. Each light fixture is designed diversely, and that means you check the provided loading instructions for this part to ensure these precision machines will operate properly to meet exact features.

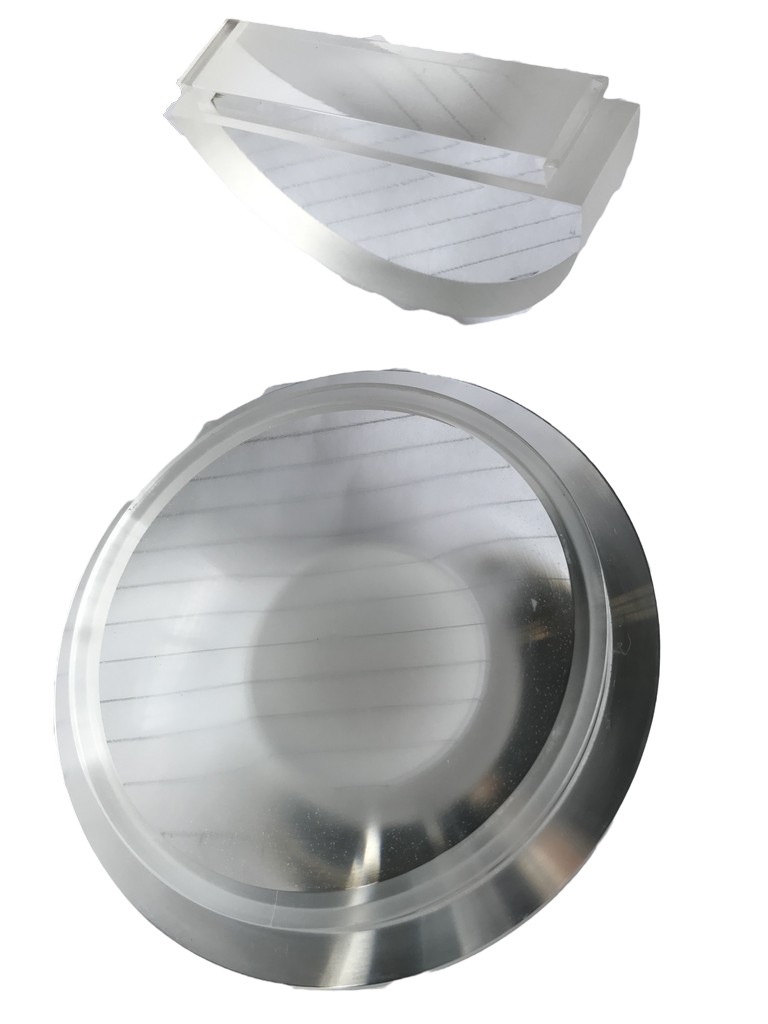

You unload a finished part to the deburring seat, where it is blown free of coolant and any small metal portions. You load a new, raw part onto the light fixture. You check that the part is properly loaded. Typically the rhythm has already started.

CNC Employees are Key to Quality Handle

An individual get back to the business on the deburring seat. Deburring, removing fastened metal chips or shavings remaining on the part after machining, helps maintain quality because debris could cause misloads or damaged pieces. Each part has clear solutions for deburring that COMPUTER NUMERICAL CONTROL operators follow.

This kind of first part needs to undergo an in-process audit, the of part measurement by using a variety of measuring tools: a caliper, bore caution, pin gages, bond gages, depth caution, and both IDENTITY and OD micrometers.

An audit program could be every 2 or numerous hours, every hour, or even every part, depending how critical the feature is to part quality. Following your audit, the part is examined by the good quality assurance on a Coordinate Gauging Machine (CMM) to verify all measurement and positions come in tolerance, not simply the critical ones included in your exam.

The Rhythm Remains

As a COMPUTER NUMERICAL CONTROL operator, you make sure your machine is running at capacity and meeting goal rates. The whole day, you also monitor the tooling used on each part to ensure that is considered performing properly. Some sort of dull tool brings about excessive burrs or out-of-tolerance dimensions. An individual watch out for part quality as you deburr them, listen for weird sounds from your machine, and pay attention to the machine’s alarm that tool life has recently been met.

After you get to the ending of your shift, you overlap for 12-15 minutes and keep your machine running for the next COMPUTER NUMERICAL CONTROL operator. You promote how the machine and parts produced for the transfer, record production, and wash up before the bell wedding rings.

From one day to the next, (or even one hour to the next), you could be using hoists to lift and move parts and equipment, cleaning and packaging completed pieces, performing changeovers, working together with another team member, or concluding up in customers.

A CNC Agent is Different coming from a CNC Machinist

An individual could have heard of another career in a CNC machine shop: the COMPUTER NUMERICAL CONTROL machinist. Think of a CNC machinist as an increasingly state-of-the-art and experienced COMPUTER NUMERICAL CONTROL operator. CNC machinists program machinery, troubleshoot mechanical issues, and read blueprints and part drawings.

Quite a few CNC machinists start out as COMPUTER NUMERICAL CONTROL operators, who now they supervise and instruct. Once employees develop in-depth knowledge of machine functioning, get to know the properties of metal, and experience numerous on-the-job COMPUTER NUMERICAL CONTROL machining, they may try to advancement.

How Does An individual Work as a CNC Agent?

Another thing many people really like about a CNC agent career is that experience is not required and training is mostly provided by a COMPUTER NUMERICAL CONTROL machine shop. On-the-job training can be put together with classes in math, 3D design, blueprint reading, and specialized CNC agent training at local technical schools or community colleges.

Quite a few CNC operators enjoy their various job responsibilities: taking on mechanical challenges, setting up up equipment, handling quality, and using hand tools and precision measuring equipment. CNC operators usually have plenty of job opportunities and earn healthy earnings.