If ever you are along the way from designing an aluminum part, that is necessary to consider which manufacturing process you use to create it. There are very different options for forming aluminum, and aluminum die casting is one of the most common alternatives for designers to take into account.

Aluminum die casting is the technique of choice for various automotive, industrial, and telecommunications goods. It 's regularily familiar with generate electrical, hydraulic, and ligting devices.

If you want to get more information on the metal die casting process and will require to some help deciding in the case it is the proper personal preference on the application, you system.Drawing.Bitmap proper place.

Deskof things

What's Aluminum Die Sending your line? The method Explained

1. The massive great things about Aluminum Die Casting

several . The most notable Considerations During Portion Style

3. How it Analyzes to Green Sand and Resilient Mold Spreading

4. Options to have Machining and Concluding

5. The most frequent Aluminum Die Sending your line Alloys

Summary

What's Aluminium Die Casting? The procedure Discussed

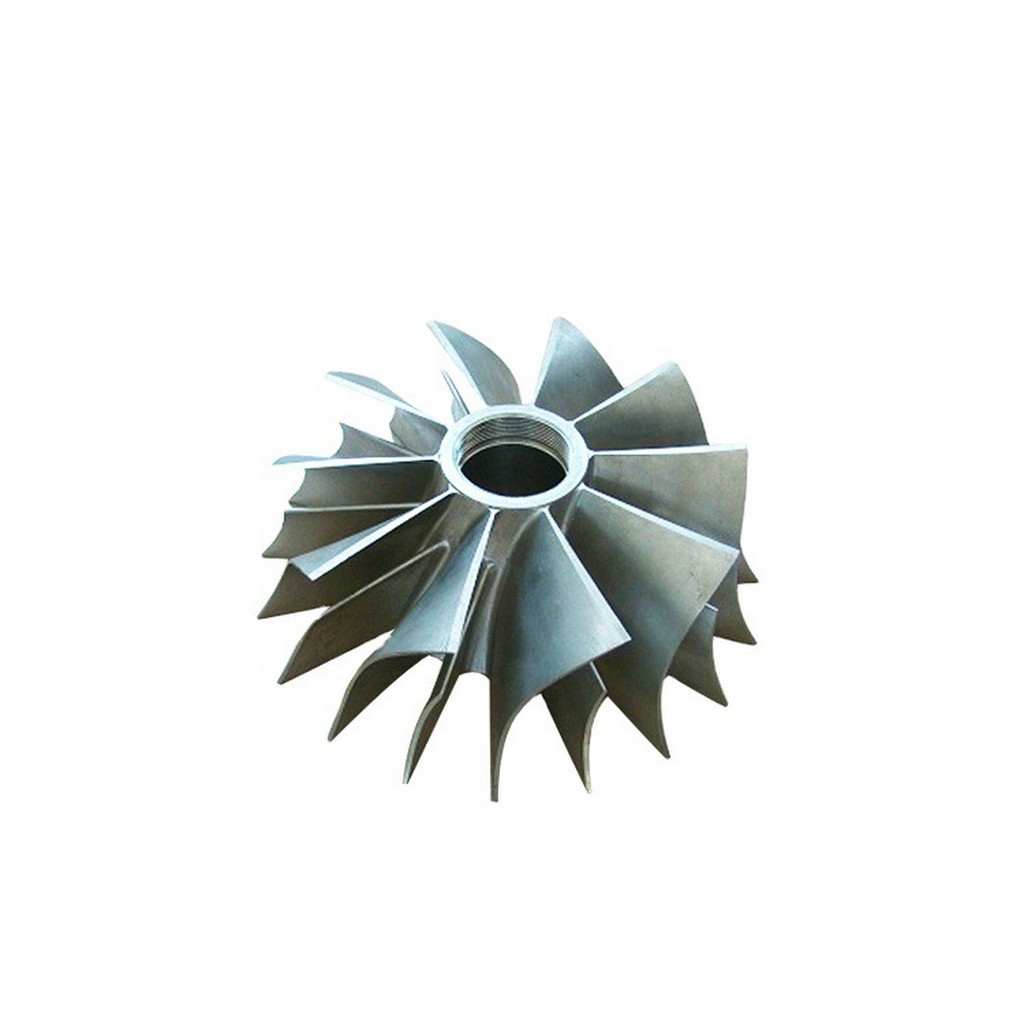

Light weight aluminumdie casting mold to have automotive parts

Large- accurate die mold for casting aluminium automotive parts

Aluminum die spreading is just a metal- creating process which allows for the creation of complex aluminum parts. Ingots of aluminum alloy are actually heated to very temperature ranges until they truly are entirely smelted.

The liquid aluminum is inserted under ruthless to the cavity of the steel perish, also referred to as a form— you will see an illustration from an impression for automotive parts above. They truly aredie is manufactured from two halves, and following the molten aluminum provides solidified, they're separated to reveal the cast aluminum in your.

The cake you produced aluminum product is certainly precisely formed with a straightforward surface and sometimes requires nominal or any machining processes. Since steel dies are employed, the procedure could be repeated many instances utilising the same mold right before it deteriorates, making aluminum kick the bucket casting perfect for the substantial- volume production of aluminium parts.

1. Advantages from Aluminum Die Casting

Die spreading aluminum offers several advantages above other metal- forming techniques which might make it a great choice to make your metal parts.

One of many most noteworthy certainly is the ability to manufacture highly complicated shapes that none extrusion nor machining can successfully create. An ideal sort from this is manufacturing from complex automotive parts, like feeds and blocks. Other processes cannot consistently achieve the complexity and tight tolerances needed for such products.

Additional advantages range from the capability to have textured or clean surfaces as well as the capacity to allow for both large little parts.

Find out more: Advantages& Disadvantages an excellent source of- Tension Die Casting

2. The best Considerations During Part Design

Variousautomobile parts created from die ensemble aluminum

Numerousaluminum parts manufactured by questionable die spreading

A couple of considerations have to be considered at any time which makes the part to turn out to be cast.

Firstly, the mold must be designed to separate your lives and then let the solidified aluminum part to . The cloths line the truth that marks where in actuality the two halves from the mold come separate is known as a parting line, and also to think about that in the beginning from die design.

Essential thought is the positioning of injections points. The die could be engineered with several injection points throughout the event if the smelted metal would otherwise solidify prior to reaching every crevice inside the die. This may also support if cavities are included during the look, it is possible to encircle associated with aluminum nevertheless 've got the business go if your mold is separated.

You need to think about the thickness from the business 's walls. There are actually usually no guidelines to your minimum wall thickness, because of recent technology developments, but having walls with consistent thickness is unquestionably often preferred.

Discover more: Aluminium Die Casting Design Guide

three or maybe more. How it Comes even close to Green Sand and Permanent Mold Spreading

Userpouring molten metal within a sand cast mold

An excellent operator pouring molten metal within a sand cast mold

Oriental sand and permanent mold are actually two common alternative casting ways to aluminum die casting. Oriental sand processes use wet crushed stone to generate the mold to find the cast, rendering it less expensive than one other two techniques. Above, you can observe an excellent operator pouring molten metal inside a sand cast mold.

Instead of die casting, which uses injections, permanent mold castings require the molten aluminum as the law of gravity poured in to the mold. Resilient mold castings also can probably produce stronger casts.

Nevertheless, perish casting offers better tolerances more enhanced- finished surfaces instead of the other two methods, generally eliminating the importance of succeeding surface treatment.

Find out more: Perish Casting vs. Sand Casting

5. Options for Machining and Concluding

Cast aluminum parts generally require minimal machining, and many choices are around for area finishing. Die casting has your great surface finish simply by casting standards but can nonetheless have imperfections, like metal joins where in actuality the mold halves match. A rough surface or many other imperfections inadequate for that portion might be addressed by sanding, sandblasting, or orbital sanding.

The cool working procedure for shot peening is frequently placed on die ensemble aluminum to enhance fatigue quantity of resistance. Alternatively, a protective or attractive coating can be used on the finished part, such since a powder coat. Some other alterations can also be used on the parts after casting, most of these as drill tapping.

5. The most typical Aluminum Die Sending your line Alloys

Aluminiumingots stacked to obtain transportation

Aluminiumingots which is often melted down for development

Some of the many frequently employed aluminum alloys to have die casting are A380, 383, B390, A413, A360, and CC401. The principal consideration when picking a suitable alloy may be the intended application.

For instance, A360 offers excellent corrosion resistance, tension tightness, and great fluidity when molten. B390 offers excellent wear resistance and high solidity whilst having the best ductility from all cast alloys, for this reason which is used for applications such as automotive blocks. Blend A380 is the right plug- of- all supports trades, supplying a good mixture of casting and product properties, and it is the most often specified blend for casting an assortment of00 products.

Find out more: Metal Die Casting Alloys Compared

Main point here

All in all , the metal- creating process you select will rely on your financial budget, the purpose of the aluminum part, and exactly how parts you make . Die casting could be a great expensive method, however it 's worthwhile if the design provides high complexity and also you call for if you are an00 of parts.

XIEJIN 's professional aluminum die casting providers include professional die design to guarantee the molten metal floods each of the parts of the shape and an ISO 9001: 2015- certified factory giving professional manufacturing with excellent substandard quality control and consistent properties. The clientfacility can be IATF16949 accredited and ISO14001 certified, and most of us provide e- coating and powder coating finishes for your castings if required by the client.