Since machining basics go, comprehending the difference between turning and milling is very important. While turning and milling are two familiar machining techniques which both remove material with a workpiece by making use of your cutting tool, each uses distinct and distinct methods to complete that, and based on a outcomes also.

In other words:

? When turning, the portion moves in addition to the tool stays nonetheless

? When milling, the business keeps still also it 's the application form that moves

Turning and milling will vary advantages, alongside capacity in terms of part intricacy and geometry. In addition, that they both produce different geometrical floors, so it 's essential to figure out which method will achieve the particular part specification when you are buying CNC machining.

Producing

Getting is a machining process accomplished by a lathe and it 's a simple machine. Within your turning machine there is a throw to support the workpiece, using the lathe spinning this workpiece because the cutting tool movements across it. It should end up having the ability to spin on the axis, however the cutting equipment work across only two responsable of motion to have specific depth, width and cut precision.

During turning, the cutting tool remains in ongoing experience of the workpiece during the whole machining operation.

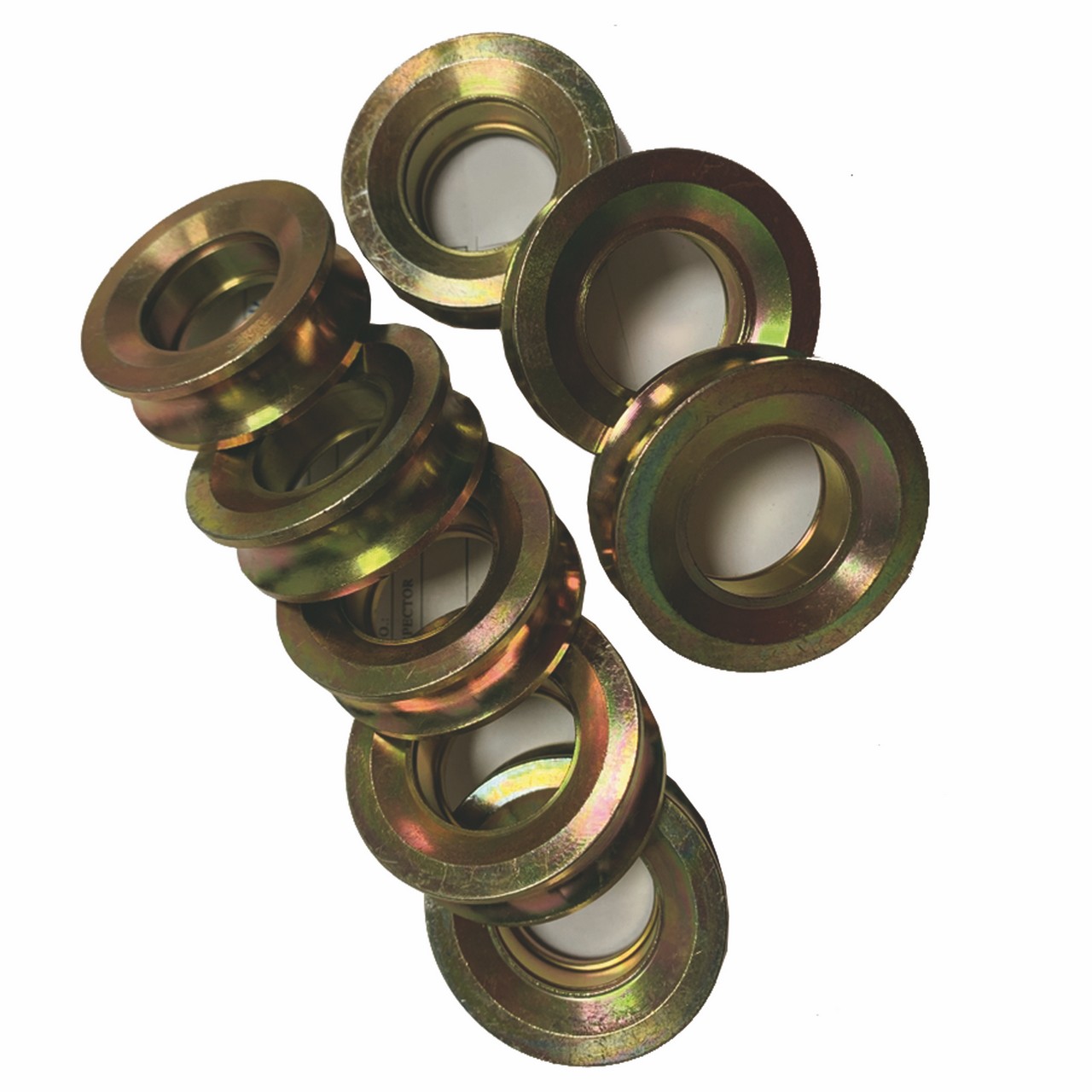

While by utilizing a turning machine is unquestionably often cheaper due it 's ease, as well as the truth that by using cheaper feedstock( bar is easier to make than billet), the styles you can make using making are tied to its characteristics. Turning reduces the diameter from a component, so parts made and made by turning must be cylindrical. This may contain basic rings through to more compound curved shapes and cones.

Milling

Milling produces parts with generally flat surfaces. Milling being a method uses rotating cutters to get rid of information, unlike turning where the application form remains still. Milling uses sporadic cutting, where in actuality the tool constantly engages, then disengages through the machining process. Milling machines can quickly create multiple slicing tool taking care of the element at once , rendering that your best option just in case the portion specification needs any off supports centre or angled machining.

Milling can cause more technical styles in comparison with turning. This is for the reason that a milling machine has as much as 5 axes of action to control- 3 thready kinds within the X, Sumado a and Z planes, as effective as two rotational axes.

That greater number of axes associated with milling also allows you to cut down on the whole circuit time required by eliminating the requirement to remove and reset the portion within a different orientation, object rendering it a quicker process. That reduced cycle time helps to machine parts faster- constantly a key consideration from your buying perspective.

One important factor to consider is that just mainly because you can use a a few axis- machine, does not constantly mean you should. For fewer complex parts or small pots, it can often be additional effective, both in lead as well as cost to use a straight forward 3 or 4 axis appliance.

Conclusion

Turning and milling are actually both subtractive machining process, even so they have distinctly different final results with your machined part. As your buyer, comprehending the differences, as perfectly as the advantages and constraints of both will ensure you pick the top machining method to get your part 's complexity and specs.