Specifically what exactly is Sheet Metal?

Bed sheet metal is actually a trusted information across a number of different industries. That may be built from an excellent range of metals like metallic, aluminum, copper, brass and it is adaptable enough used during various applications, including commercial and manufacturing. Sheet metal can turn out to be precisely manipulated because of their flexibility, durability, and ultimate ultimate tensile strength, offering advantages to the current designer.

Way of measuringDevices

Sheet metal thickness determines the correlating terminology— plates, bedding, or foils. Foil thickness is certainly generally defined around zero. 2 mm, with sheet steel which range from 0. 5 logistik to six mm. Anything earlier mentioned 6 mm is defined as a metal platter.

Three different units measure density: gauges, millimeters, and mils. See could be the metal 's thickness during regards to the weight every square foot, with a larger gauge indicating a thinner bed sheet of metal.

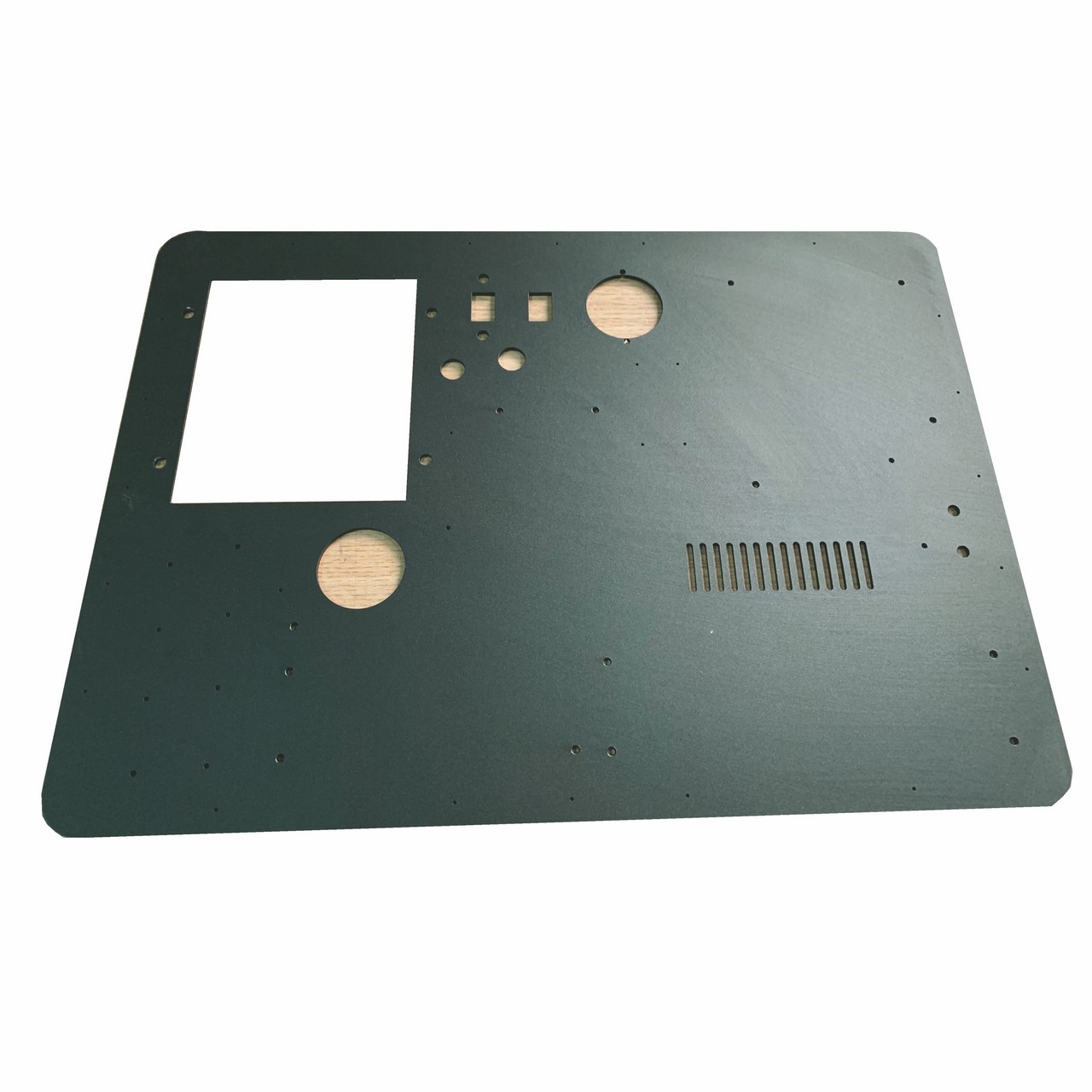

page- steel- laser- cutting

Your bedsheet Metal Manufacture

Sheet metal manufacture uses sheet metal to construct machines, structures, panels, brackets, and much more. There really is not one method of form or use bed sheet metal, and that's why that's popular across different applications. Forming processes put in a extended report on techniques, including:

Plastic materialstamping

Metal stamping can be your cold- forming process. Dead and stamping presses are used to control sheet metal in numerous shapes for a lot of applications. Stamping is quick and cost- effective, which is ideal for creating a great deal of perfected elements. A few of the machining approaches inside the stamping process are embossing, bending, and coining.

Twisting

Since its name implies, bending is the process of shaping sheet metal into desired shapes. Metal is unquestionably typically bent in regards to one axis. The target is to bend the metal over a yield point but under the ultimate tensile strength.

MoveForming

Spin forming is the method from feeding metal through rollers to make a uniform bend over the entire entire sheet metal sheet making coil.

Extending

Stretches a skinny sheet of steel is all about as easy for the reason that it sounds. Metal materials are expanded or separated using different hand tools or machines.

Cuttingwith CNC Machines

Sheet steel cutting in industrial/ manufacturing applications happens to be a precise process that uses computer numerical control( CNC) equipment like lasers, plasma, waterjet, and so on . CNC machines are used to produce precisely engineered parts. Autodesk 's Pier 9 workshop posseses an remarkable sample of CNC machines. If ever thinking about working together with metal, automated systems are your human 's companion.

exactly whatsupports is- sheet- steel

Kinds of Sheet Metal

With respect to the desired application and manufacturing process, sheet metal can simply contain a number of different steel types. Aluminum and steel could be the most versatile metals and are in fact utilized across various applications.

Aluminium

Though it is probably not since strong as steel, aluminum is surely a great lightweight alternative. Capabilities well at low temperatures, thus it will always be used during cold climate applications just like a fridge, aerospace engineering, roofing, etc.

Stainlesss steel

Steel is strong and adaptable, with in your few different subgenres: stainless, zinc coated steel, carbon steel, and dark- colored iron steel.

Copper mineral

Copper is unquestionably usually useful for decorative applications but is yet a superb conductor and corrosion- resilient.

Magnesium (mg)

Magnesium is actually a stiff and sturdy metal using a low density. Recently, a brand new magnesium alloy was produced for that automotive aftermarket that may substitute aluminum within the body solar panel systems of some automobiles.

Metal

Instruments is a good metal to obtain fittings and components. The hearing properties and corrosion resistance from brass let it ended up being perfect for instruments and firefighting equipment like nozzles, fittings, and wrenches.

Dureté

Having a low melting point and superior durability to copper, bronze is required to create coins, decorative structure, and wires.

Blend360 Piece Metal Workspace

Ready to design bed sheet metal parts? XIEJIN 's Fusion fish hunter 360 is a built-in CAD/ CAM application which includes a sheet steel workspace lets you design assembling your project with developing at heart. Features just like the one Flange Tool, which combines five flanging commands( base, border, contour, miter, and swept) in one single command, set an individual- friendly tool for creators in any way levels.