Areas to consider whenever choosing the proper casting process.

Casting is a definite from the oldest manufacturing tactics dating back to to 1838. When the fundamental casting process not changed much, today 's machines are already more complex with within technology, a big several several ways to reach finally your ending product— or part so to talk about. Two common and extremely identical processes are die casting and investment casting. Continue reading and we'll discuss the main between each one of these process and help you to be familiar with benefits and drawbacks from each this means you can opt for the best process to your upcoming project.

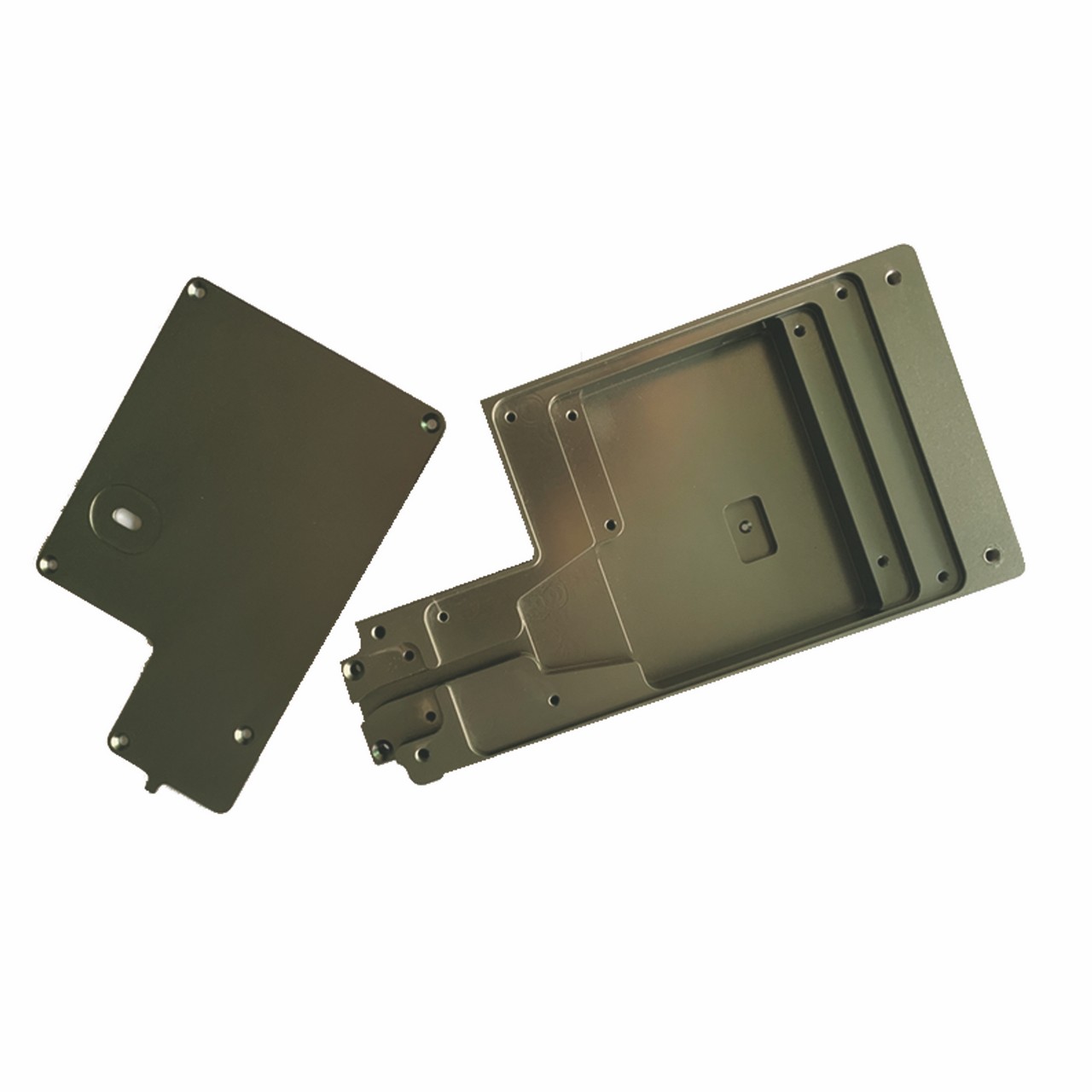

TheDie Casting Course of action

Simply put, when die sending your line a part, molten metal can be injected into a hardened material die cavity. When the material solidifies it is ejected via the tool as well as process can be repeated. The process varies a little bit determined by the material you choose— see hot chamber and cold slot provided die casting. The hardened material Mould is capable of constructing anywhere from 150, 000 photographs to over a million photographs before it would need to be repaired or replaced.

Typically theInvestment Casting Strategy

Creating some part using the investment audition or "lost wax" process is usually a more time- drinking process where a wax original of your part is built and then repeatedly dipped right into liquid ceramic. Then yourceramic firms and then a wax may be melted out getting out of the relationship using a ceramic Mould. Molten material is then poured into your porcelain cavity where the wax used to be . Once the metal solidifies, the ceramic Mould is broken and removed leaving the metal sending your line. The Mould used to make the wax pattern works extremely well plenty of times however the ceramic Form is broken and discarded with each part. However, Signicast features automated every aspect of the investment casting process making one particular week lead times possible in which the industry average is almost 8- 16 weeks.

Which Course of action Is Right for My Venture?

No two casting projects happen to be the same and with several projects, there is different solutions. Below are a few things to consider before starting your next venture to help you choose which will process is right for the component.

MaterialSelection

Most cease to live cast parts are made of non a considerable ferrous metals like zinc, Lightweight alloy, and magnesium. Investment casting can be capable of casting cast these metals along with ferrous alloys, including stainless steel. If you are looking to make work with of a non- metallic material, both processes offer identical features. However, if you happen to be looking to use stainless terme conseillé or copper alloys, investment sending your line is a better option.

AnnualAmount

When deciding which casting practice to implement, decide what your ideal payback period is for the tool cost. Just how plenty of parts created versus the price tag on the tooling to "break even". When investment casting tooling may always be cheaper and well suited for lower amount projects, die casting is suitable for larger production runs and superior- volume projects.

Tolerance

With any casting process, tolerance functions are largely influenced by the design with the part and the material used. The table listed below compares general linear tolerances pertaining to conventional die casting and expenditure casting. The multi- go die casting process is competent of holding even tighter tolerances.

DIMENSIONAL TOLERANCE COMPARISON

DieAudition Investment Casting

Up to 25 mm+/- 0. 050 mm+/- 0. 250 mm

Up to 50 mm+/- 0. 075 mm+/- 0. 350 mm

Up to 75 mm+/-. zero. 100 mm+/- zero. 400 mm

Close to 100 mm+/- 0. 125 mm+/- 0. 500 mm

** Please allow up to 0. 025 mm for each additional 25 mm

PeriodTime

When investment casting and die audition both produce complex parts, the cycle times differ greatly. Common investment casting serves as a timely strategy that will require really somewhat from Labour and hours of, when die casting can deliver several- 4 shots per little for conventional die casting and also 45 shots per little with multi- slide expire casting. A die cast portion can often times be made without the touch of some human hand— complete automation!

Cost

Circuit time determines up to 60% of your final part charge so it is no big surprise here, that per part, expenditure casting generally costs more as opposed to die casting. Its highly manual processes yield parts very identical to that of a expire casting, but the cycle time period is really a lot longer .