Material Casting Processes

6. 3 EXPENDITURE CASTING

Investment casting, just like die casting( which may be discussed over these section), could form areas of similar geometric forms and size. Since, once you will probably learn below, the disposable style is produced by injecting wax tart to an impression, features which have been difficult or expensive to treatment mold or cast( e. g., undercuts) will also be expensive to expenditure cast.

Investment casting is usually employed when low production volumes happen to be expected( e. g., less as opposed to 10, 000 pieces), whereas expire casting tends to be employed when high production volumes happen to be expected.

Investment cast parts could possibly be manufactured from an array of fabric alloys including aluminum and realtor alloys, carbon and low combination steels, stainless steels, tool terme conseillé, and nickel and cobalt metals. Die castings, when you will learn next section, should be on a mining harvests with relatively low melting temperatures— primarily zinc and aluminum.

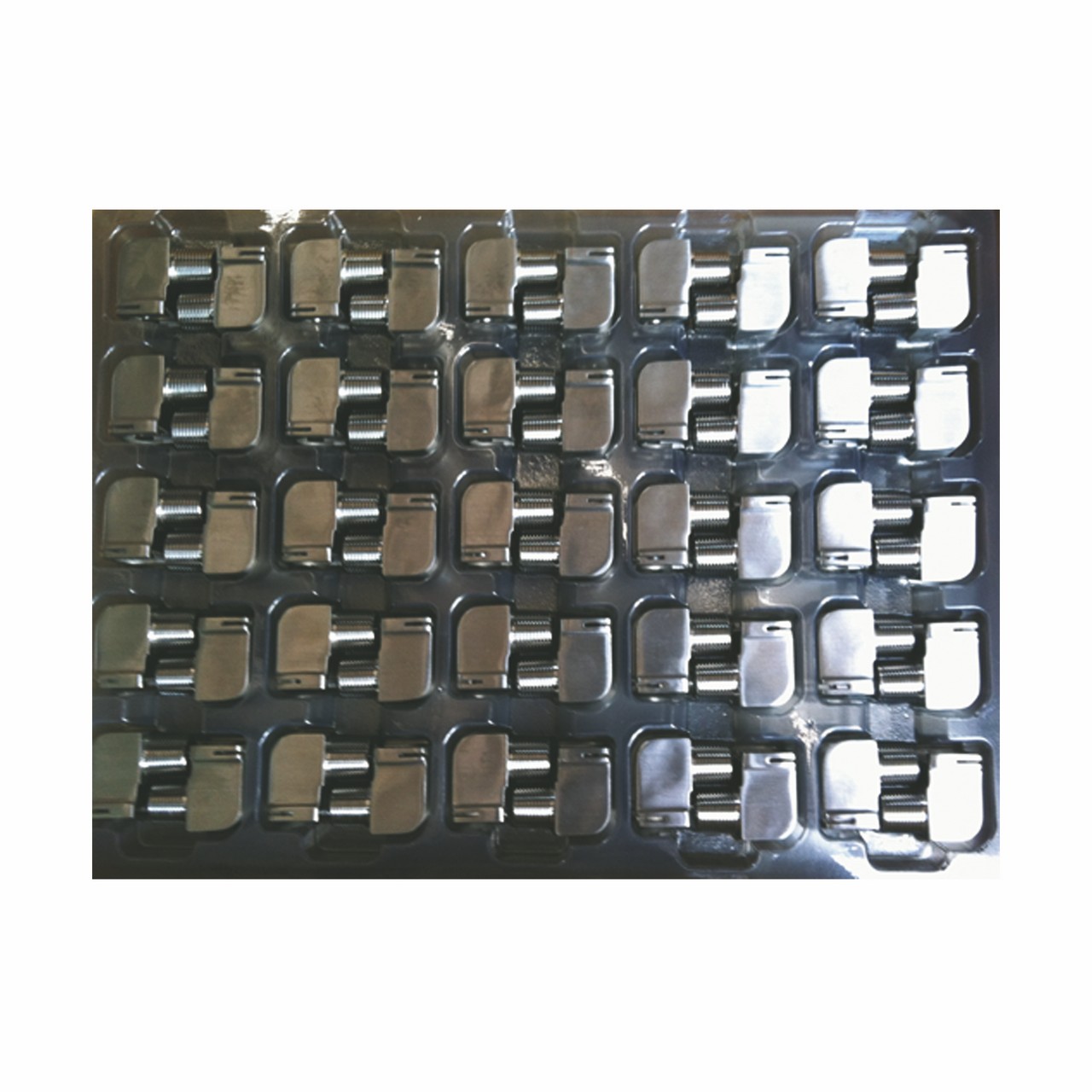

In expenditure casting( Figure 6. 5), some metal die or mold can be produced by either machining along with casting. The shapemore difficult the proper execution( due to undercuts, regarding example), the more expensive the metal dies.

After the mould is formed, wax is being injected to form a pattern. Theexternal form of the wax tart pattern resembles the internal kind of the mold. The wax tart pattern is taken from the mould and attached to a wax tart base that contains a entrance. If the production volume can be adequate several wax patterns happen to be placed on a tree that is made up of the runners, gates, and different features that will feed and distribute the molten metal. Some metal hollow tube is actually located over the wax patterns and a slurry— such as plaster from Paris— is poured to completely cope with the patterns. The completed mould depend on the oven plus the wax removed by reducing and evaporation. Next the mould is generally positioned in the second oven to cure for doze to 24 hours.

To generate parts, the mold cavity can be filled with molten metal the fact that is allowed to solidify. To facilitate filling of the mould the melt is poured when the mold remains to be hot. The moment the part has cooled, the mold is destroyed as well as portion removed. The tolerances and exterior finishes achievable by investment audition are such that machining will be generally required.

The type from machine being used is conveniently specified based on the task to be used . The selection from a single suitable machine can be simplified further by your fact the fact that only those machines from the manufacturing Department can be deemed. The best way in terms of these component is to think about every one process selected and the equipment obtainable in turn.

Casting

Expenditure casting has been obviously known as the process to work with to form your initial billet. While such there is no tools selection problem as there happen to be only two casting processes and associated equipment available, only one particular of which is an expenditure casting process. Finally the power/ force analysis is just for subject material removal processes and is for that reason inappropriate.

Turning

There is four lathes available, two NC and two manual machines, and any one particular of the four machines should certainly be able of turning the face. In addition, this method is also carried out on the CNC machining centre. Therefore, the next stage of the collection method should allow a few of these machines to get discounted.

Drilling

Thedrilling tools selection appears to be some straight choice between the COMPUTER NUMERICAL CONTROL drill and the drill press. However, the drilling and spotfacing could also be carried away on the CNC machining hub and the two milling models. Therefore, the equipment selection difficulty for these procedures is extra complex than it first may well seem. As with turning, the power/ force analysis stage to get used to reduce the multitude of applicant machines.

Running

The grinding procedure requires an enclosed maker to be used . As there may be just one internal grinding unit from the machine shop, there can be no equipment selection problem.

Expenditure casting is generally intended for having complex- shaped parts the fact that require tighter tolerances, thinner wall surfaces and better surface finish as opposed to can be obtained with yellow sand casting. The distinguishing feature from investment casting is the means the mould is done. A style of the part is built from wax, which is then simply dipped into fine ceramic slurry that contains colloidal silica and alumina. The mould is dry and heated in the oven to melt out the wax going out of behind a ceramic shell mildew for casting. The investment sending your line method, also called the shed wax process, is utilized pertaining to precision casting of aerospace parts such as gas turbine knives. Theinvestment casting of lightweight alloy alloys results in lower toughness than sand castings, but offers you tighter tolerances, better surface surface finish and the capability to develop thin- walled sections.