The aim of modern CNC milling is to change materials such as metal castings into finished, usable components. That goal is merely achievable by using incredibly precise COMPUTER NUMERICAL CONTROL milling machines.

Personal computer software is the brains of any COMPUTER NUMERICAL CONTROL (Computer Numerical Control) milling machine, managing the machine and automating production to increase throughput with steady quality. It may be this repeatability that produces CNC machining so efficient and so valuable to both customers and the machinists themselves (see “The Machinist’s Perspective” throughout this article. )

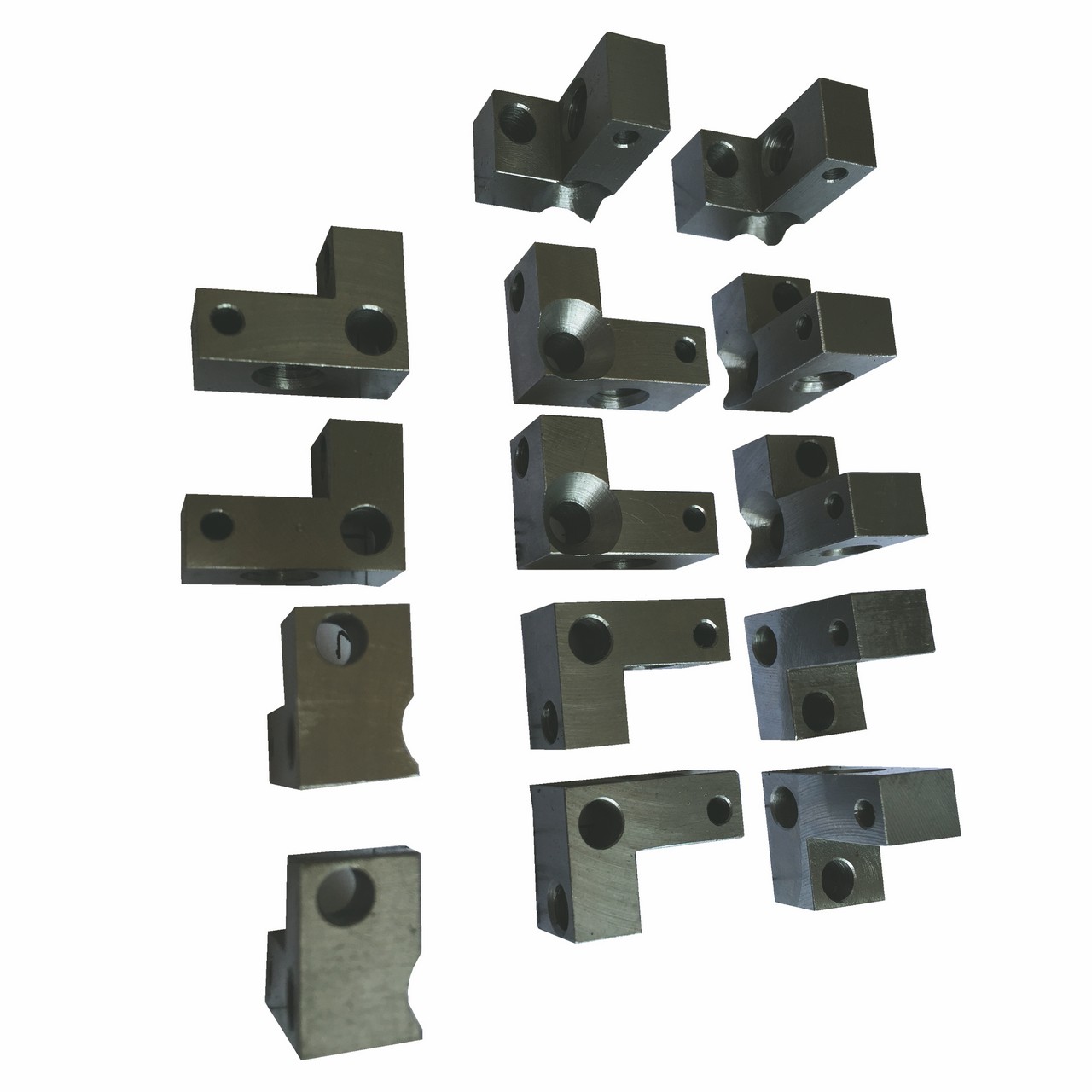

The conclusion results? Custom precision machined parts that meet exact specifications in large quantities while reaching extremely limited tolerances. Highly skilled machine operators understand that CNC milling machines are not only important to their jobs but additionally to the producing industry and the impact on the planets economy.

What Really does a CNC Milling Machine Do?

The particular thrill of being a CNC machinist is transforming a casting into a part which you can use and trusted, often within a larger product. These parts often require tight tolerances, which unfinished libéralité don’t have before to functions done by a COMPUTER NUMERICAL CONTROL milling machine.

Toned Surfaces — COMPUTER NUMERICAL CONTROL face milling places flat surfaces on a workpiece. Deal with milling creates a finished sealing surface so flat that potential leak issues are practically eradicated.

Drilled Holes — Drilling creates a hole, and going adds threads. By means of and tapped openings are the most prevalent way to assemble pieces. Drilling focuses on the two diameter and depth of the hole.

Bored Gaps — Enlarging an existing hole employing a drill and a stiff boring rod with a single-point cutting tool varieties a precise interior cavity within a workpiece. Boring allows parts to be assembled properly and tightly (achieving very tight tolerances for diameter) or for valves to persistently control the move of air, engine oil, or gas.

As soon as it comes to “tight tolerances, ” how tight are we talking? Some sort of CNC machine can cut as correct as 0. 001” (single-digit micron range), or about .25 the width of an human hair. Together with that’s done in an incredible speed.

Typically the Machinist’s Perspective — Seeing the change for better of a illuminating into a done spend a small tolerance is a rewarding and persistent accomplishment. Maybe honestly, that is why CNC milling machines keep employees so engaged.

Precisely how Does a COMPUTER NUMERICAL CONTROL Milling Machine Do the job?

A detailed information of each and every CNC milling machine would require a complete series of blog posts! Here is the most significant thing you have to know: Range of action is an integral aspect of CNC milling, and it ascertains exactly what do be completed by the mill’s tooling. In COMPUTER NUMERICAL CONTROL milling machines, that includes 2-, 3-, 4-, and full 5-axis options.

CNC-Machine-Axis-1

2-Axis Machine — Used for handbook fixture building; activity is simply on the x and y axes; not a lot of repeatability

3-Axis Machine — Used often in vertical milling; activity on x, y, and z responsable

4-Axis Machine — Most usual CNC generator; movement on a, y, and unces axes with an extra b axis, to allow the table to move allowing access around a workpiece; usually limited to lateral machines, yet state-of-the-art shops also use 4-axis vertical machines (normal vertical is 3 axis)

5-Axis Machine — Activity on x, y, z, and t axes and further a-axis; these are area of expertise milling machines; not suitable for high-volume development parts

Vertical as opposed to Horizontal Machines

You will discover two main spindle orientations in COMPUTER NUMERICAL CONTROL milling machines. Throughout vertical CNC machines, the spindle axis, which is called the z-axis, is oriented vertically. Throughout a c-column setup, the spindle vacations in this route, and the stand which holds the workpiece moves in both x and y horizontal guidelines. Vertical machines are simply perfect for high-volume, active projects milled from one side, such as covers and brackets.

In lateral CNC machines, the spindle z-axis is horizontal and typically parallel to the size of the machine. The spindle travels the usable y-axis and flat in the x-axis. The pallet and fixtures hold the workpiece and move in the z-axis, and the b-axis rotates. Horizontal engineering has several advantages: accessing machining from four sides, performing multiple businesses on the same light fixture, milling more complicated parts, more increased chip evacuation.

Typically the Machinist’s Perspective — It’s exciting to use an in-house design department that has learned the machines and knows the employees, creating an productive workflow.

Can COMPUTER NUMERICAL CONTROL Milling be Blended with Other Surgical procedures?

With computer motorisation and engineers’ thoughts, CNC milling machines have the potential to mill virtually anything imaginable. These kinds of incredible machines also allow for additional businesses to be included to the milling process, providing increased functionality.

For example, a lathe could first remove a bulk of a part’s material (which is faster than profile milling), creating any needed rounded turns. Then, the business can be milled, with gaps drilled, taps included, and so out A single user controlling both generators in a single cell, or work center, can create a complete part. Not having multiple work facilities and operators boosts efficiency.

The Machinist’s Perspective — Getting able to complete multiple tasks back-to-back not only provides CNC machine user a sense of accomplishment, it confirms a reliable and valued position within the shop.

Precisely what are Xiejin’s CNC Milling Machine Capabilities?

Zero two machine outlets are the same, with each finding unique market niche categories and developing their own manufacturing talents.

Xiejin Machine is an example of a contemporary, high-end shop in a position to handle many CNC milling jobs. Although equipment is regularly updated to meet customer demand, when this informative article was written, Xiejin’s COMPUTER NUMERICAL CONTROL milling machines include 61 horizontal generators and 14 up and down mills.

Based on creation demands, 95 per cent or more of such may be working during a typical first shift, departing the mediocre available for setup. Having over four times as many horizontal COMPUTER NUMERICAL CONTROL milling machines as vertical claims something special in Xiejin’s give attention to complex elements demanding tight tolerances.

In addition to standard milling tools, Xiejin also utilizes specialty tooling when needed. For example, one tool was custom ground to possess all three diameters into it that would normally be achieved with about three separate drills.