COMPUTER NUMERICAL CONTROL Milling is a specialized type of COMPUTER NUMERICAL CONTROL Machining; if you would like to determine read more about CNC machining, check out our complex guide. Computerised manages produce a custom-designed part or product of top quality and precise finish off. It is preferred in many market sectors for the accuracy, reliability, and ability to increase production and uniformity. The milling process starts with a CAD painting (computer-aided design), and it is employed to regulate the outputs of the CNC Milling machine.

CNC symbolizes Computer Numerical Handle, which means that a computer manages the milling machine. If you would like to determine read more about COMPUTER NUMERICAL CONTROL machining, check out and about our in-depth guide.

Read on for a detailed look into the COMPUTER NUMERICAL CONTROL Milling process, the anatomy of a CNC machine, and different types of CNC milling available.

This introductory guide will supply an release to CNC Milling, and will cover the following:

What exactly is a COMPUTER NUMERICAL CONTROL milling machine?

How can CNC Milling work?

What does a CNC Milling Equipment do?

CNC Milling Method

Features of a Milling Equipment

Types of COMPUTER NUMERICAL CONTROL Milling

How much does CNC Milling cost?

Benefits of CNC Milling process

What is a CNC milling machine?

A milling machine manufactures high-quality pieces to a high level of aspect and finish. COMPUTER NUMERICAL CONTROL milling machines use rotary tools to cut away at the material, with instructions originating from the CAD data file, to build the part design. The purpose and coordinates of the cutter are manipulated by the milling machine's computer, with minimum people input wanted to complete manufacturing.

CNC milling machines are constructed to mass-produce many components from various materials and materials. The core purpose of a milling machine involves by artificial means cutting away at a workpiece in the desired shape.

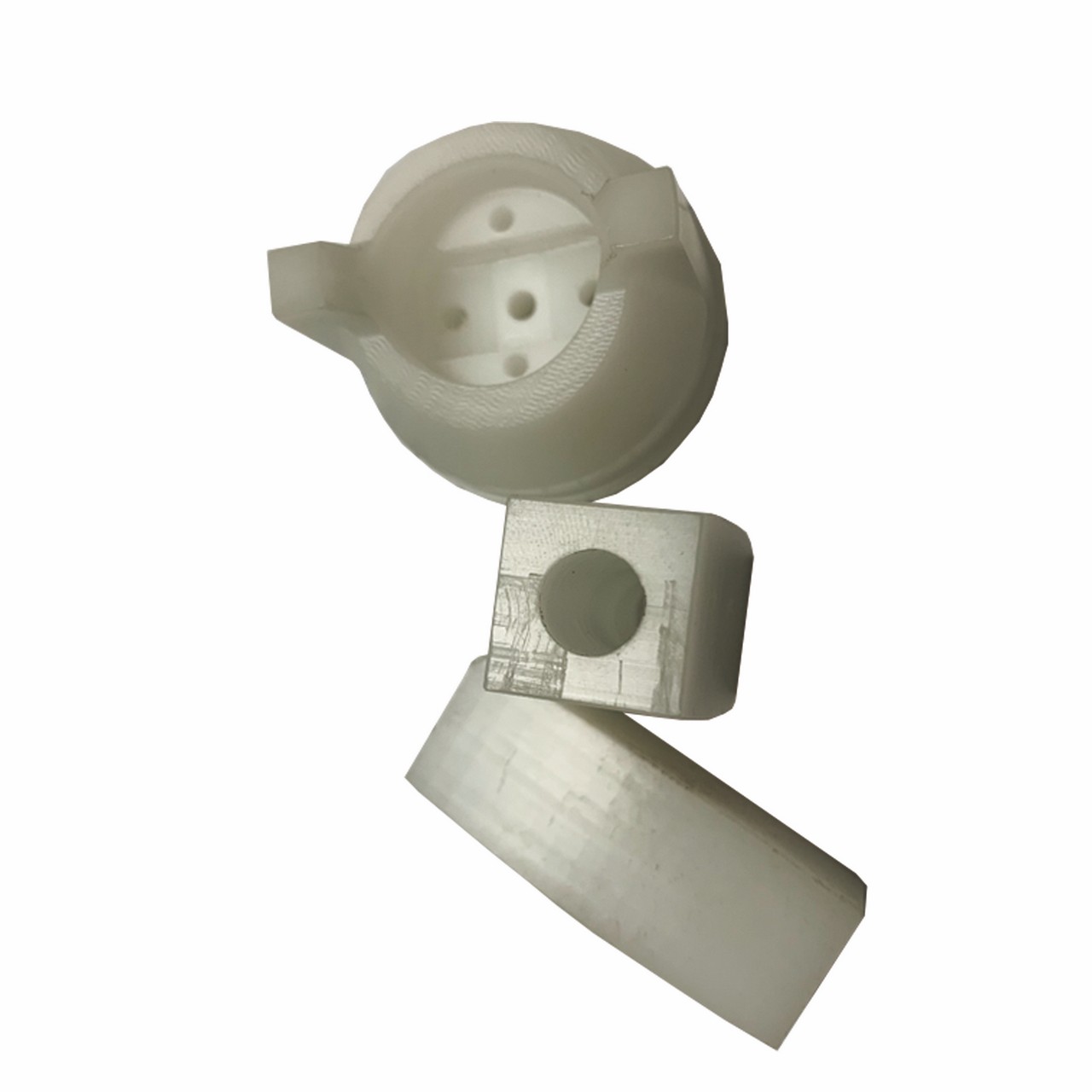

Cnc machined Grey Anodised

How can CNC Milling work?

The CNC Milling process works by your machine reading coded instructions and then putting them into operation. It all starts with possessing a 3D CAD data file representing the ultimate part. Once completed, the structure is modified into a machine-readable format. CAM (Computer-Aided Manufacturing) software then exports this to a CNC machine program, usually in G-code format, which acts as the instructions, directing every move that the machine makes. This kind of replicates the CAD design in the chosen material with good accuracy and efficiency.

Click here for more information on CAD and the technology needed for CNC Machining.

Employing subtractive machining technology, CNC Milling can produce high and low volumes of highly complex and intricate parts. Product is taken from a blank workpiece, and the milling machine uses a spinning cylindrical tool called a milling used vinyl cutter. Depending on the milling machine being used, your machine can cut in several facets and move alongside different axes.

One more part will have first been designed via CAD, or Computer-Aided Design, before being inputted in the milling machine for final production.

computer numerical control machine machining an aluminium aerospace part

What does a CNC Milling Equipment do?

A COMPUTER NUMERICAL CONTROL milling machine makes intricate parts for several industries using subtractive machining technology. The milling machine cuts away at the workpiece and crafts one more part via the 3, 4 or 5 axes. Depending on variety of axes the CNC milling machine has, the more complicated and complicated one more piece can be. A COMPUTER NUMERICAL CONTROL milling machine is employed by various market sectors - including space and medical industrial sectors - to make complex parts.

COMPUTER NUMERICAL CONTROL Milling Process

Several milling machines will be more appropriate than others, dependent on various factors. The complexity of the CNC milling process will be dependent on the design of the ultimate part. The more structurally important and high-end the part or method, the more complex the look may need to be.

For occasion, a more intricate machine may need to be used for intricate designs requiring finely-detailed, such as medical or aerospace components. This specific is to achieve the final design, finish, and cosmetic. Basic parts that are machined for more general use may well not require such high precision or high-quality finish. Intricate and intricate designs will typically require additional milling.

Usually milling machines utilize either 3, 4 or 5 responsable.

For simpler elements, fewer axes are essential to achieve the final design. Basic geometries can generally utilise a 3-axis milling machine. They will are easy to program and operate, reaching excellent reliability at a low cost. The slicing tools are linked to a spindle that works on three linear responsable. They might spin at 1000s of RPM, which means however, sturdiest of materials can be cut through with ease and reliability.

3-axis machines are the most typical variety of milling machines and can cut top to bottom (Z-axis) and in an X and Y direction. On the other hand, it’s usually not possible to machine undercuts with a 3-axis milling machine. These are features that cannot be accessed with a standard conclusion work. This means that more complicated designs may require an even more intricate milling machine.

The particular 4-axis milling machine is more superior, with the additional ability to turn on the X-axis (similar to a lathe).

5-axis milling machines include rotator both in the Times and Y-axis. They will are the most satisfactory milling machines available and are implemented for highly complex designs such as medical devices and implants for the medical industry, impellers and space structures.

Top Hint: Read our guide understanding the COMPUTER NUMERICAL CONTROL Milling process

Major Tip: Read our guide How to Machine Square Four corners with CNC Milling

Attributes of a Milling Equipment

The main features of a milling machine can generally be compacted into seven different parts. These features include:

Knee - The knee is fixed to the column, but it can be changed. It supports the saddle and the worktable. It can be lowered or raised on the Z-axis.

Column - The column is the key support design for your machine. That works as a reinforcement for one other machine parts.

Typically the saddle - Typically the saddle is located in the knee and under the worktable and it can be moved seite an seite to the axis of the spindle. It moves the workpiece horizontally if needed.

The worktable - The area located on the top of seat where the workpiece is fastened. Typically the milling machine’s worktable can be variable, with respect to the type of machine, and be used vertically and horizontally.

Spindle - This is a rotating component that holds either the machine tool or the arbour, plus its driven by the motor.

Arbour - The arbour is employed in horizontal milling machines. It is inserted into the spindle and works as a the whole length which can be used to build different machine tools.

Ram - Typically the ram is normally found in usable milling machines, plus its fixed to the top of the collum the location where the spindle is supported.

Device tool - The particular machine tool is the component that performs the milling operation. It is held by the spindle and gets rid of materials from the workpiece. There is an array of machine tools.

Haas CNC Milling Machine

One of a CNC Milling Device, courtesy of Haas.

Types of COMPUTER NUMERICAL CONTROL Milling

Vertical milling

With vertical milling, a 3-axis milling table is the work surface, which sits under the arm, to which a spindle is attached.

The spindle can be immobile if the vertical turret gun mill is used. In this situation, the table shifted along both Times and Y responsable. Meanwhile, the desk only moves together the X-axis if a bed up and down mill is used. The spindle journeys across the length of the arm in the Y-Axis way.

Horizontal milling

Together with horizontal milling, the spindle operates flat rather than vertically, and all sorts of components are similar to vertical milling. Generally speaking, side to side mills are best suitable for heavier jobs or longer jobs. Also, they are suited to parts that need a huge amount of substance to be removed as the swarf falls away from the part and cutter.

Face milling

The cutting tool’s axis of rotator is perpendicular to the surface of the workpiece.

This employs face milling cutters, with the teeth both on the periphery and the tool face, the latter which can be used for finishing software. Face milling is also used to create flat floors and control a finished piece. Experience milling can produce high quality finishes than other milling functions and is appropriate for vertical and lateral milling machines.

computer numerical control face milling aluminium lightweight block

Plain milling

The cutting tool’s axis of turn is parallel to the surface of the workpiece. Simply milling cutters have teeth on the periphery that perform the cutting functioning. Both narrow and wide cutters are being used. This allows for deeper cuts and for larger surface areas to be worked on. A program and fine-toothed used vinyl cutter are both used. Slow cutting rates and fast give rates are widely-used for the course used vinyl cutter and vice versa for the fine-toothed cutter. This permits a more precise final part.

Slanted milling

This is a milling functioning where the chopping tools’ axis of rotation is at an angle relatives to the top of workpiece. Thus, single angled milling cutters can produce more angular features, such as bands, serrations, or chamfered edges.

Form milling

Variety milling is the most suitable used for milling businesses where more unpredictable surfaces are engaging. Contours, outlines, perimeters, or parts with curved, flat floors. It employed milling cutters or journey cutters specialised for particular applications ~ for example, cavité cutters or area rounding cutters. Hemispherical or semi-circular designs or other in the same way intricate designs with complex parts would gain benefit form milling technique.

Types of a Milling Equipment

As there are several types of CNC milling, there are also various of unique milling machines with distinct characteristics and functions. Some different types of milling machines are:

Ram-type: This machine allows the equipment tool to manoeuvre on the XY axes through a spindle that is attached to a movable equip on the line. Horizontal milling machines are often ram-type.

Knee-type: Knee-type machines will vertically modify the worktable as opposed to the spindle. The leg will lower and enhance the worktable together the column to reach the machine tool. Plain milling is often done on the knee-type machine.

Planner-type: The worktable is fixed together the YZ responsable in this milling machine with spindles that are able to move together the XYZ responsable. They can also simultaneously support upward to four machine tools.

Bed-type: These types of milling machines have the workpiece set below the trimming tool. The machine tool may be able to move across the XYZ responsable.

Just how much does COMPUTER NUMERICAL CONTROL Milling cost?

The particular cost of COMPUTER NUMERICAL CONTROL Milling is reliant on various factors. The expenses of CNC Milling mostly stem from how long it requires to machine each item. Longer milling times could be a consequence of needing to remove considerable amounts of material or hard materials. Depending on the part design, some parts may involve more complicated tools or cutting. Some other factors that determine the expense of CNC milling are material and part complexity. A person can just click here to arrange a COMPUTER NUMERICAL CONTROL Milling quote with the team at Have it Made, or else learn more about our COMPUTER NUMERICAL CONTROL Machining services.

Advantages of CNC Milling process

Top quality and precision is assured

The very character of CNC Engineering as a process leaves very little room for mistake and high levels of accuracy and precision. This is because it works from a computer led program, typing 3D designs which may have been developed via CAD (Computer-Aided Design). All functions are launched via a machine interface.

The particular machine executes these instructions with no need for guide input. These automatic processes allow for ultimate precision to ensure however, most finite and complicated geometry can be technically managed.

COMPUTER NUMERICAL CONTROL Machined Parts Acidity Etched aluminium

COMPUTER NUMERICAL CONTROL Milling allows for high production result

The amount at which CNC Machines operate means they are effective at high levels of production because of to the automatic processes involved. COMPUTER NUMERICAL CONTROL Milling is a trusted and popular option in case a part needs to be produced in high volume, with every part meeting the same degree of regularity in phrases of quality and handle. This is particularly easy to program and operate a 3-axis machine, reaching high accuracy at an affordable.

CNC Milling is a less labour intensive process

Utilizing a CNC Milling Machine significantly reduces the labour included in the manufacturing process. At total capacity, the tools utilized in a COMPUTER NUMERICAL CONTROL Milling machine can spin at countless numbers of RPM (revolutions per minute), producing in high manufacturing output while also being a time-saving expense. No guide processes could achieve a similar result. It’s worth observing that the easier the design is, the less human being intervention is needed. For instance, if a complicated design required the empty to be relocated in the process, this would include machinists to ensure the process was completed safely.

COMPUTER NUMERICAL CONTROL Milling machines with uniformity

CNC engineering tools are made and developed to cut away at the workpiece with the greatest levels of precision. The movement is directed from the computer program, which means every single part is produced to the same degree of accuracy. On a broader scale, components can be produced in high quantity, with the producer safe in the knowledge all completed parts will have the same standard and finish.

Xiejin is an established unique manufacturing partner for high precision COMPUTER NUMERICAL CONTROL Milling and Engineering. Get in contact to discuss your project’s requirements and kick-start your manufacturing. Arrange a CNC Milling quotation today, and our team will get back in twenty-four hours.