Will be your Machining

Partner Trustworthy?

You can find plenty of COMPUTER NUMERICAL CONTROL machine shops, but finding one you can actually depend on is also a history. If you’ve ever before worked with an unreliable machining spouse, then you know how stressful and frustrating it can be parts are unavailable, out of spec, or postponed.

At Advance COMPUTER NUMERICAL CONTROL Machining, we expect you should be able to have the elements you need, if you want them. You should not have to struggle with your machine shop to get things done; instead, you should feel confident they’re working with you to help you keep production on plan with high-quality elements.

For us, youre not merely another order, and we’ll work together with you so you get quality work, punctually, from people who care — every day.

Lovers in Performance

and Top quality

Our objective is to generate opportunities for our households and our neighbours. And with Makino, we can do just that.

Our company is excited to work with Makino, one of a global leaders of the CNC machining world, to bring our customers the quality work that is synonymous with Progress CNC Machining.

Need to whatever we can do? Check out there our videos with Makino and see what they say about our quality level.

Advance CNC includes old school beliefs with new institution technologies.

We understand how overwhelming it can be when \ what you need, when you need it, creation problems that never to end. That is why we’ve already been helping companies like yours since 1987. With two locations, over a , 000, 000 dollars of customer parts in supply, and the best highly accurate machines, we help customers nationwide get the parts they need, when they require them. We’re here to deliver in every possible way, providing:

Reliable service from our entire team, including dedicated bank account managers who know your order

Excellent value through fast machining centers, brief lead times, extra services, and a stocking program

Top quality craftsmanship made possible by the very best high-precision COMPUTER NUMERICAL CONTROL machines and trained machinists around.

Qualifications

CNC stands for computer numerical control. The evolution towards the current point out commenced with NORTH CAROLINA, or numerical control only.

The initial NORTH CAROLINA machines were built in the forties and 50s. These kinds of machines based on existing tools but with some changes.

Motors moved structured on the educational input given to them via smacked tape. The signal was manually smacked into data greeting cards.

In the 50s, the first steps towards CNC engineering were done. With first, MIT’s pcs were all set to produce the punched strapping in line with the inputs. Throughout one instance, this reduced the time invested in producing the card from 6 hours to twelve to fifteen minutes for a milling job.

The of Numerically Manipulated Machine Tool - NC and CNCThe History of Numerically Controlled Machine Instrument – NC and COMPUTER NUMERICAL HANDLE

Such time-saving functions resulted in more R&D work in the field. Rapidly the first coding languages for COMPUTER NUMERICAL CONTROL machining became available. Over time, generally because of lessening computer prices, COMPUTER NUMERICAL CONTROL took over the reigns from NORTH CAROLINA.

Just how can CNC Equipment Work?

Contemporary COMPUTER NUMERICAL CONTROL machines are totally automated. All they need is digital files with the instructions about reducing trajectories and pedaling.

Design or engineering processes require many tools to produce a certain part. Machinists can build digital tool your local library that interface with the physical machine. Such machinery can automatically switch pedaling based on the digital instructions, making them manufacturing workhorses.

The CNC engineering process depends on designing the pieces in CAD software. The 3D model determines the necessary dimensions and properties of the ultimate part.

Many of these programs come in CAD-CAM packages, hence the stream can continue in the same programs. Otherwise, CAD models are fed into designated CAM software. If both CAD and CAM are from the same product family, no translation of data is necessary. In any other case, the CAD data need to be imported.

CAM (computer-aided manufacturing) software works on the model for the whole architecture process. First, it checks the model for errors. Next it provides an impressive COMPUTER NUMERICAL CONTROL program to fabricate the physical part.

The program is, in essence, a set of runs that guides the cutting head in the manufacturing process.

Typically the 3 rd step is choosing the right parameters. For instance , reducing speed, voltage, Rpm, etc. The setup is determined by the angles of the business as well as being the available machinery and tooling.

Lastly, the software program determines the having their nests. Nesting means the orientation and keeping of parts comparable to raw stuff. The purpose is to maximise the material usage.

Most this information can then be translated into requirements that the machines can understand ~ M-code and G-code.

G-Code vs M-Code

CNC Coding ExplainedCNC Coding Explained

The misconception is that G-code is all you need for running machining businesses. However, this is not true, as the code can be separated in the two codes stated previously.

G-code refers to a language that can be used to notify a machine how to move. Fundamentally, it is the geometric code. G-code determines the movements and speed of cutting heads.

Typically the instructions are provided to a machine controller which is merely an business computer. This, in return, requires how the motor should move. Plus the motors, of course, determine the course to be implemented.

The M-code, on the other palm, gives all the info that the G-code overlooks. Honestly, that is why it is called either machine code or assorted code.

M-code’s instructions include information about the use of coolant, tool change, program stops, and so forth.

So the two are equally important but not the same.

Get your metal fabrication offer in seconds

image

Quote in just a few seconds

image

Short prospect times

icon

Shipping and delivery by Fractory

Find offer

What Is definitely CNC Machining?

And so, we now learn how CNC machines work. But not all these machines are employed for CNC engineering.

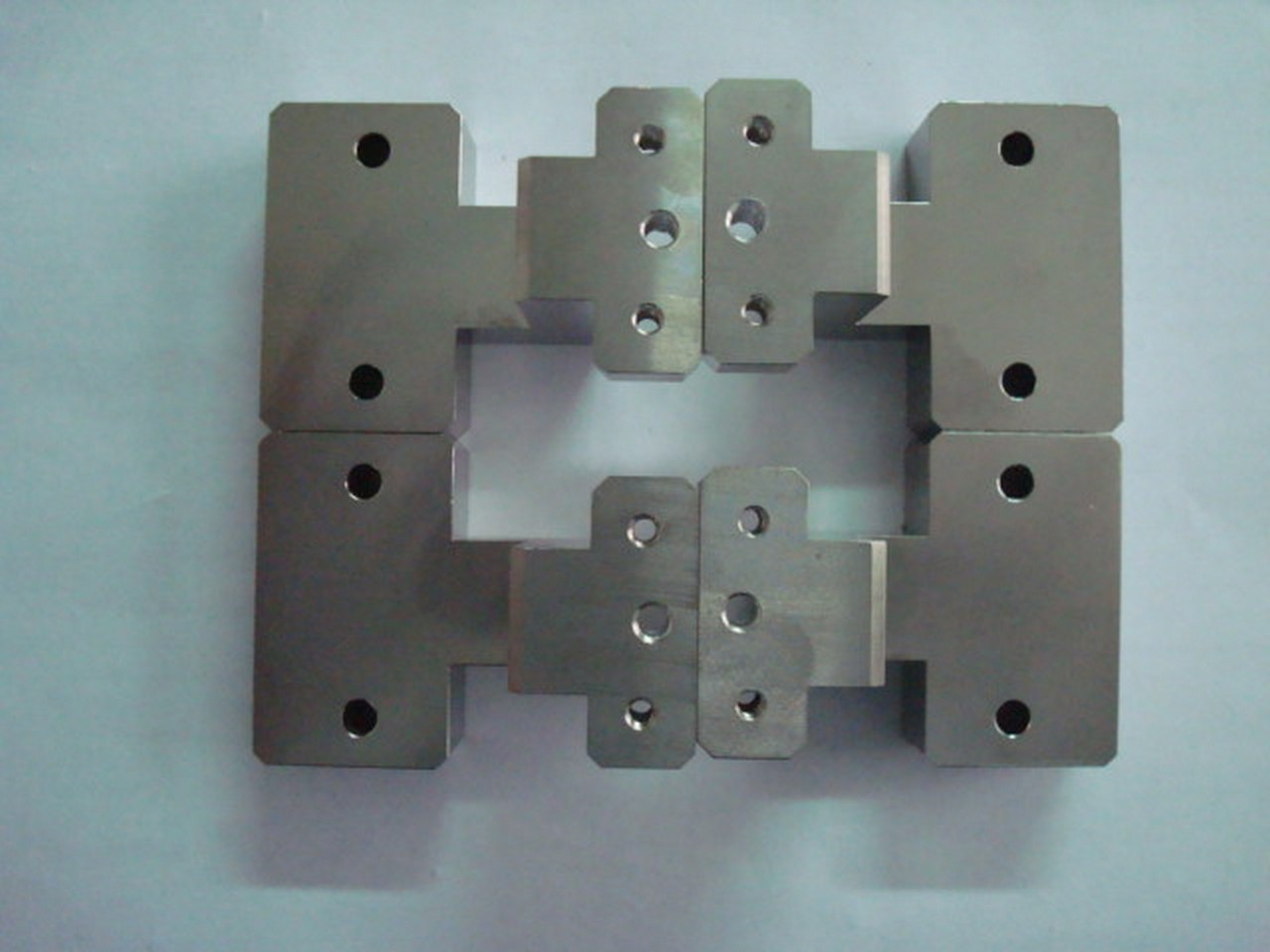

We will require a closer look at all the several types of CNC machines available a little later. But also in a traditional sense, COMPUTER NUMERICAL CONTROL machining refers to only some of these automated processes. Particularly milling, turning, running, routing, drilling, and so forth.

Milling

CNC milling machine for action

That is an functioning where cutting tool rotates. When the milling tool comes into contact with the workpiece, it removes chips from it.

Milling functions include:

End milling

Chamfer milling

Confront milling

Drilling, uninteresting, tapping, and so forth

It is a very general fabrication method with great accuracy and tolerances. Milling is suited to a variety of materials and is also very quick. The cabability to create a variety of complex pieces is a great advantage.

The negatives include a sizable amount of waste, need for a variety of tooling and high cost of equipment.

Turning

COMPUTER NUMERICAL CONTROL turning machine

Even though the two are often called just CNC machining, converting and milling have distinct differences. Converting is pretty much the other of milling. Consequently as opposed to the cutting tool, the workpiece is spinning.

CNC turning is commonly used for producing shafts, for example. The tool is brought against the rotating workpiece to cut off components of material, known as debris or swarf. Obtaining high accuracy for a suitable sort of limits and will fit system is possible.

Turning is practical externally of a cylinder or on the inside. Typically the latter functioning is called boring.

Farming

CNC grinding machines use a spinning grinding wheel to clear out material. The purpose is to give a high finely-detailed finish to a metal part.

Typically the achievable surface quality is very high. Consequently, it is employed as a finish functioning rather than resulting in the final piece from raw materials.

Course-plotting

CNC routers are seemingly similar to CNC milling machines. Here also the rotating piece is the cutting brain. The main big difference lies with the materials well suited for chopping.

Routers are a perfect fitting for cutting softer materials (not metals) that do not require very high exactness. The true reason for that is its lesser productivity power.

At the same time, routers are quicker. Thus, most suitable option produce the parts in less time.

Drilling

Even though milling equipment can also produce gaps, drills are recommended for only that job.

The? Even though milling tools use cutting edges around the cutting head’s periphery, drills use the tip of the tool to produce a ditch.

CNC drilling machines are commonly used to automate this job, provide better accuracy and a more cost-effective solution.

Types of COMPUTER NUMERICAL CONTROL Machines

As said before, CNC machines are not constrained to the original sense of CNC engineering equipment.

CNC is widely used to automate a variety of different architectonics methods. These include:

Laser cutters

Sang blades

Waterjet blades

Flame cutters

Hit braking

Milling machines

Turning machines

Routers

Electrical discharge machines, and so out

All these businesses greatly benefit from the automation factor. This reduces a persons factor in one more quality, enhances repeatability of processes and accuracy.

The information above about the workings of COMPUTER NUMERICAL CONTROL machines apply to every one of these methods. As soon as consulting a laser light cutting service for example, the same logic applies ~ the cutting journey is automatically made.

This process like numerous others, however, does indeed not need most of the extra information like the change of tooling. For the reason that the same chopping head is well suited for the whole life long the process.

What Can COMPUTER NUMERICAL CONTROL Machining Make?

Relatively, CNC machining is without limitations. It is well suited for a variety of materials, including different types of metal, materials, foam, composites and wood.

3-axis milling machines will be able to produce almost all of a lot more basic geometric shapes. To get more complex pieces, multi-axis milling organisations are available.

COMPUTER NUMERICAL CONTROL Machining CapabilitiesCNC Engineering Functionality

For example, a 5-axis COMPUTER NUMERICAL CONTROL milling centre can help out. Even though the more common 3-axis speculate if this trade 3 thready axes of activity, 5-axis machines can also rotate the cutting head and the machine cargo area.

This significantly increases the overall flexibility and also increases the cost. Though CNC is a lot more rapidly, manual machining keeps having its place in the. Especially for low-volume rapid prototyping.

But CNC engineering still prevails in the sector when high accuracy is necessary. This is the reason why so many market sectors take good thing about it, including:

Aerospace

Electrical power

Protection

Mining

Professional equipment

Food & drink

Clothing

Auto

Product design, and so on.

Overall, CNC engineering has cemented the put in place the production sector as a reliable and useful way of production parts. At the same time, COMPUTER NUMERICAL CONTROL machining cost may often be a little bit higher compared to other fabrication methods.

The particular machinery itself comes with a higher price and is difficult to operate, posing some risks. Thus, the best you to get machined parts is consulting a company who has the required expertise to guarantee top-notch quality.